13, Iscon Industrial Estate, Near Iscon Temple, Nugar Bypass, Mehsana-384 205 Gujarat, India

13, Iscon Industrial Estate, Near Iscon Temple, Nugar Bypass, Mehsana-384 205 Gujarat, India

Hygienic seals are used widely in virtually all sanitary applications to seal clamp connections in sanitary pipe lines.

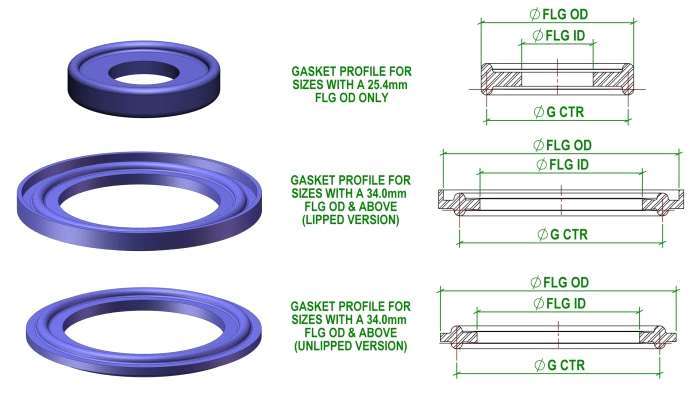

TYPE OF TRI CLAMP GASKET :

TRI-CLAMP GASKET DIMENSIONS :

| Nominal Size INCH |

ID INCH |

ID MM |

OD INCH |

OD MM |

BEAD INCH |

BEAD MM |

|---|---|---|---|---|---|---|

| ½ | 0.4 | 10.2 | 0.87 | 22 | - | - |

| ¾ | 0.64 | 16.2 | 0.87 | 22 | - | - |

| 1 | 0.9 | 22.9 | 2 | 50.5 | 1.71 | 43.5 |

| 1½ | 1.39 | 35.3 | 2 | 50.5 | 1.71 | 43.5 |

| 2 | 1.88 | 47.8 | 2.52 | 64 | 2.22 | 56.5 |

| 2½ | 2.39 | 60.5 | 3.05 | 77.5 | 2.78 | 70.5 |

| 3 | 2.88 | 73.1 | 3.58 | 91 | 3.29 | 83.5 |

| 4 | 3.85 | 97.7 | 4.67 | 119 | 4.33 | 110 |

| 6 | 5.8 | 147.2 | 6.57 | 167 | 6.16 | 156.5 |

| 8 | 7.8 | 198 | 8.56 | 217.4 | 8.15 | 207 |

| 10 | 9.74 | 247.4 | 10.55 | 268 | 10.12 | 257 |

| 12 | 11.74 | 298.2 | 12.56 | 319 | 12.17 | 309 |

APPLICATION :

KEY FEATURES :

Technical Data :

| Physical Properties | Test Method | Units | Typical Values |

|---|---|---|---|

| Specific Gravity | DIN EN ISO 1183-1 A | g/cm3 | 1.1 |

| Hardness, Shore A | D2240 | SHORE A | 60 |

| Tensile strength psi(Mpa) | D412 | MPA | 11 |

| Elongation (%) | D412 | % | 440 |

| Tear Resistance, Die B lbf./in. (KN/m) | D412 | KN/M | 24 |

| Tensile Modulus @100%psi(Mpa) | - | - | - |

| Temperature Rating | - | °C | -40 TO 220 |

| Compression set 22h@175°C | ASTM D395 method B | % | 31 |