13, Iscon Industrial Estate, Near Iscon Temple, Nugar Bypass, Mehsana-384 205 Gujarat, India

13, Iscon Industrial Estate, Near Iscon Temple, Nugar Bypass, Mehsana-384 205 Gujarat, India

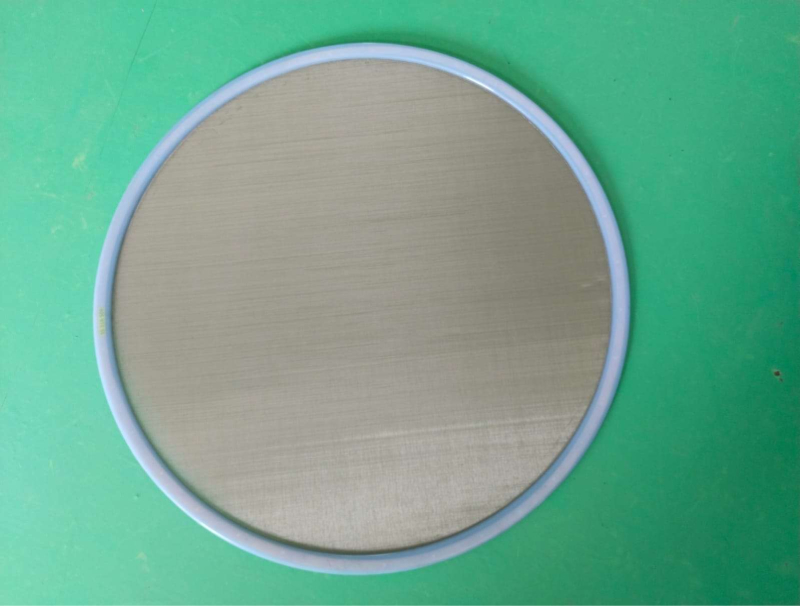

Vibro Sifter Sieves for the most part utilize vibration vitality or a mix of Vibration & ultrasonic energies to accomplish screening. Sifters must be uniquely intended to oppose the high elastic pressure created. Since Particle Size Distribution has a crucial impact in sedate disintegration, keeping up the exactness of the strainer gaps is a fundamental piece of sifter fabricating. Appropriate thickness of wire, precise ostensible opening sizes, high elasticity & rigidity of the strainer are basic for high filtering execution.

Vibro Sifter Sieves Application :

Salient Features of Vibro Sifter Sieves :

Technical Specifications :